Glazing

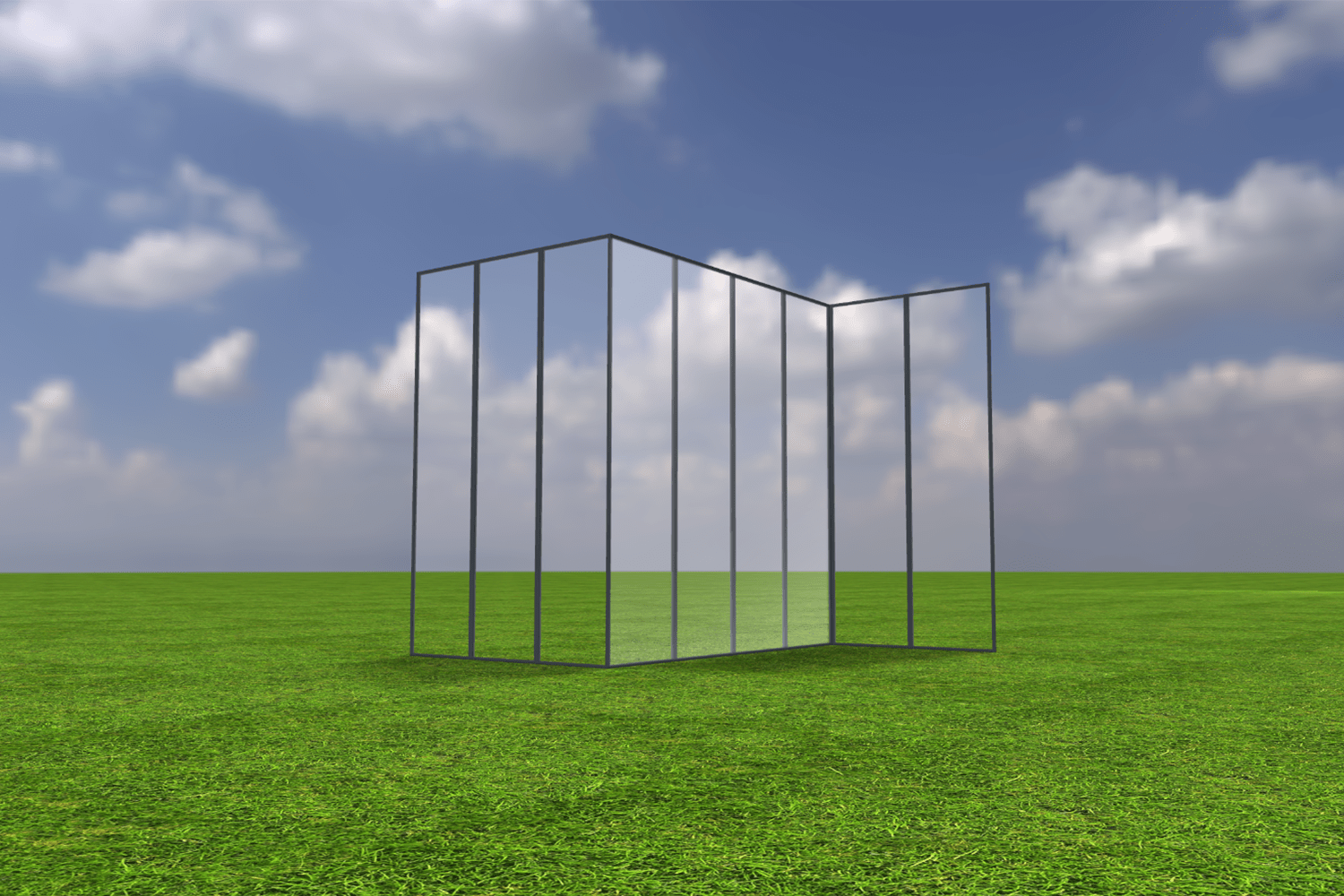

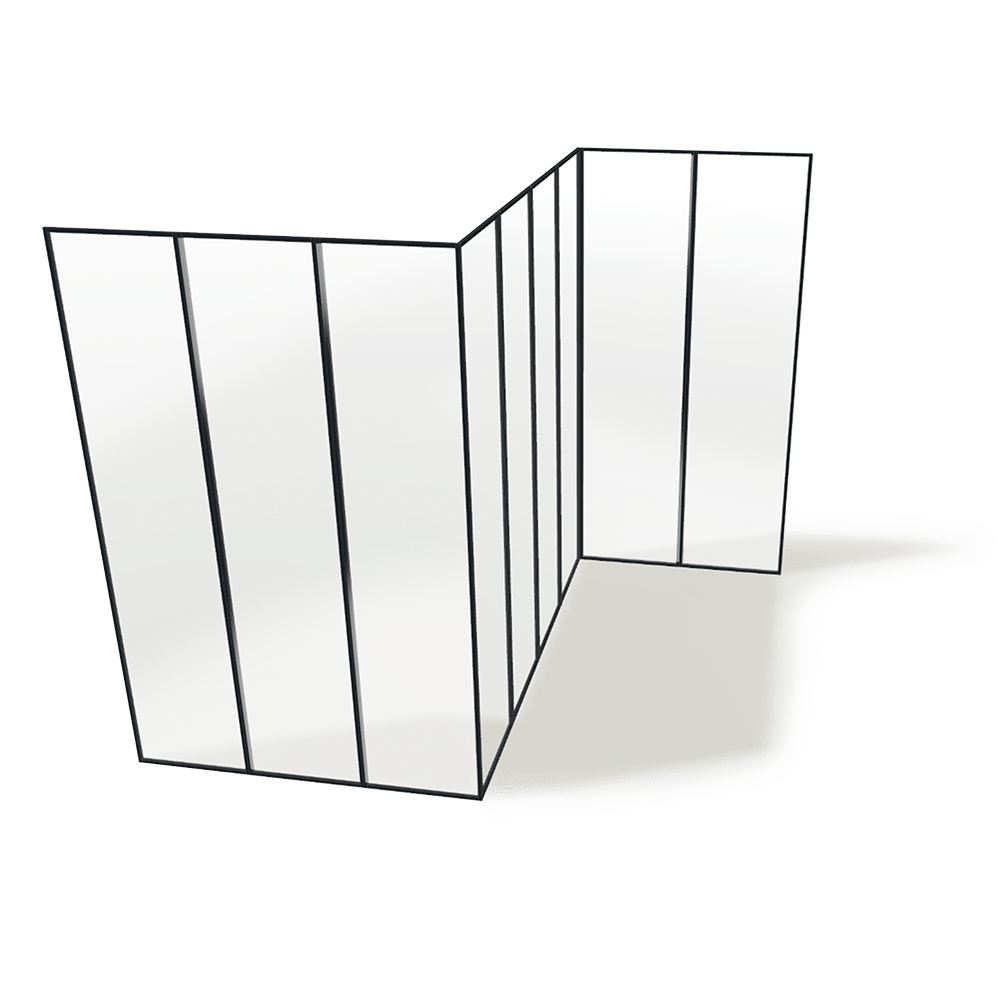

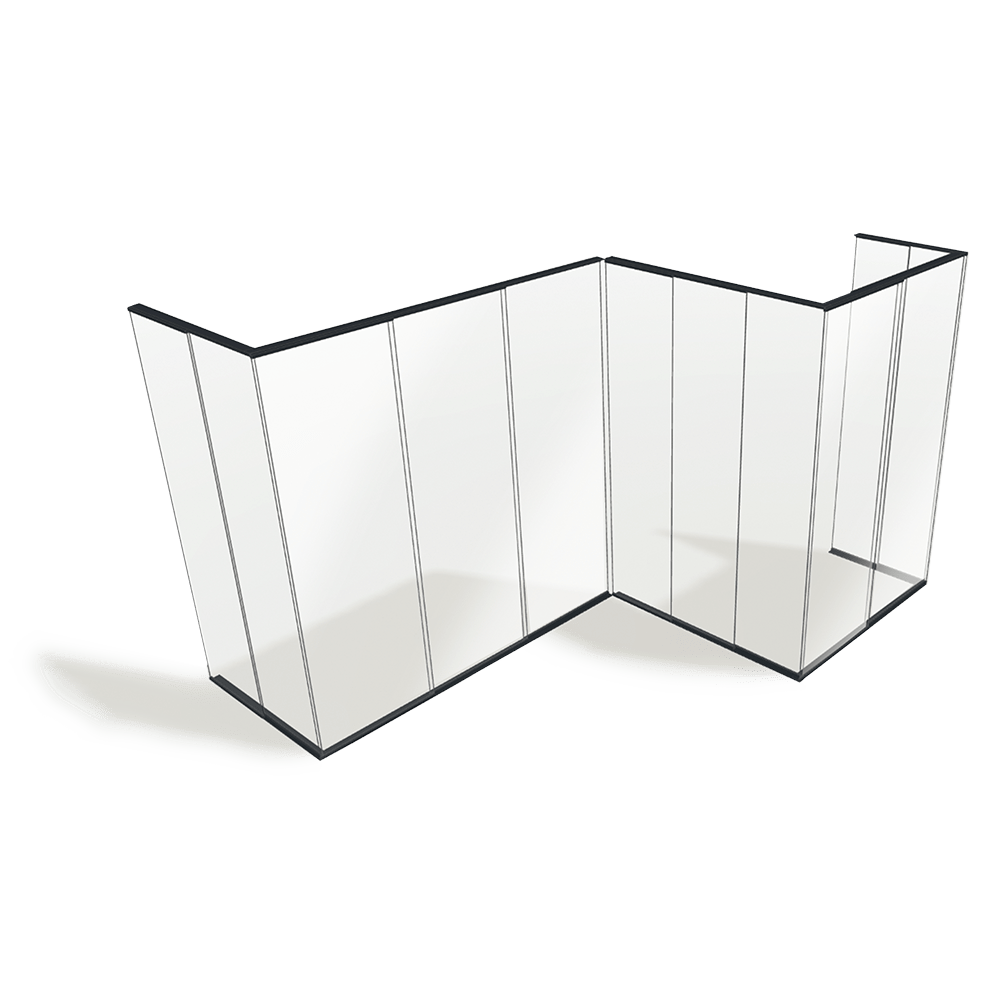

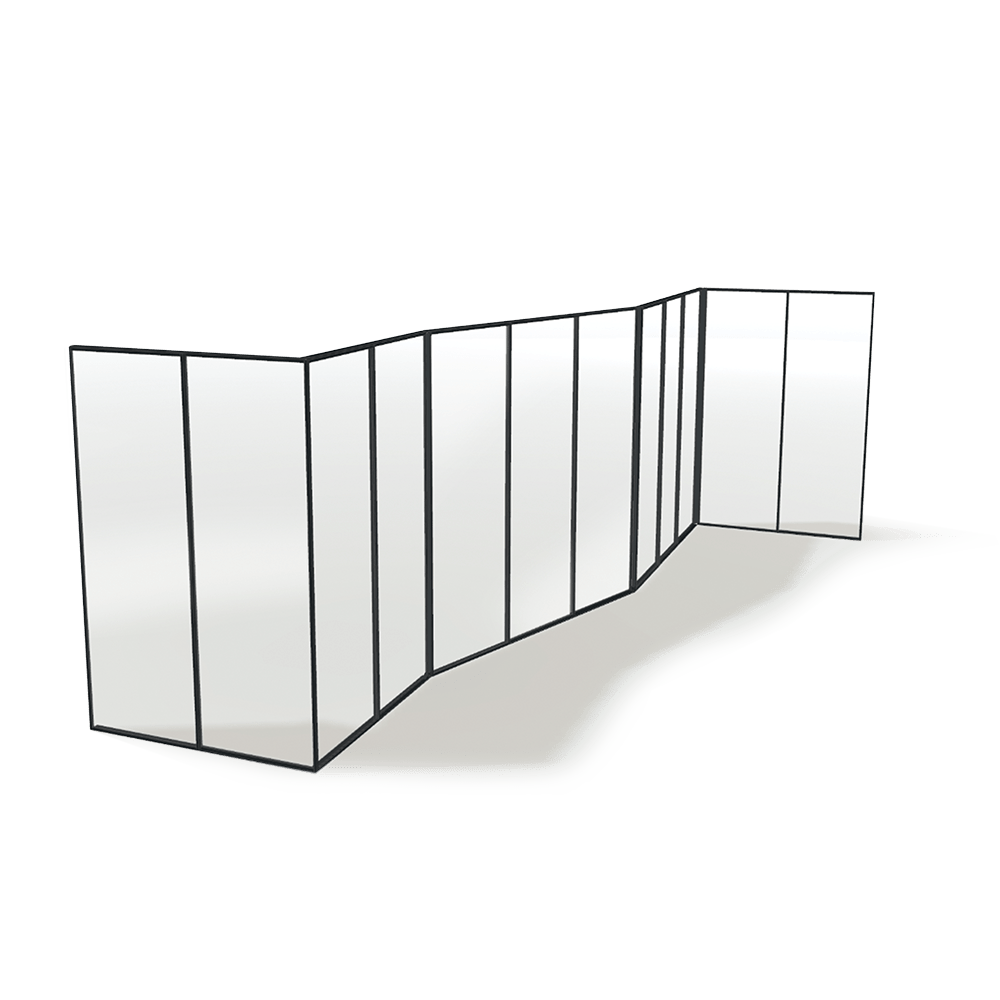

The drawn glazing line is filled with a glass product, divided into parts according to the rules and the parts form a desired whole, e.g. a sliding door (frameless or framed), folding window door, reversible sliding door or fixed glass wall. The structure can fill an opening from the floor to the ceiling or it can start from the top of the balustrade.

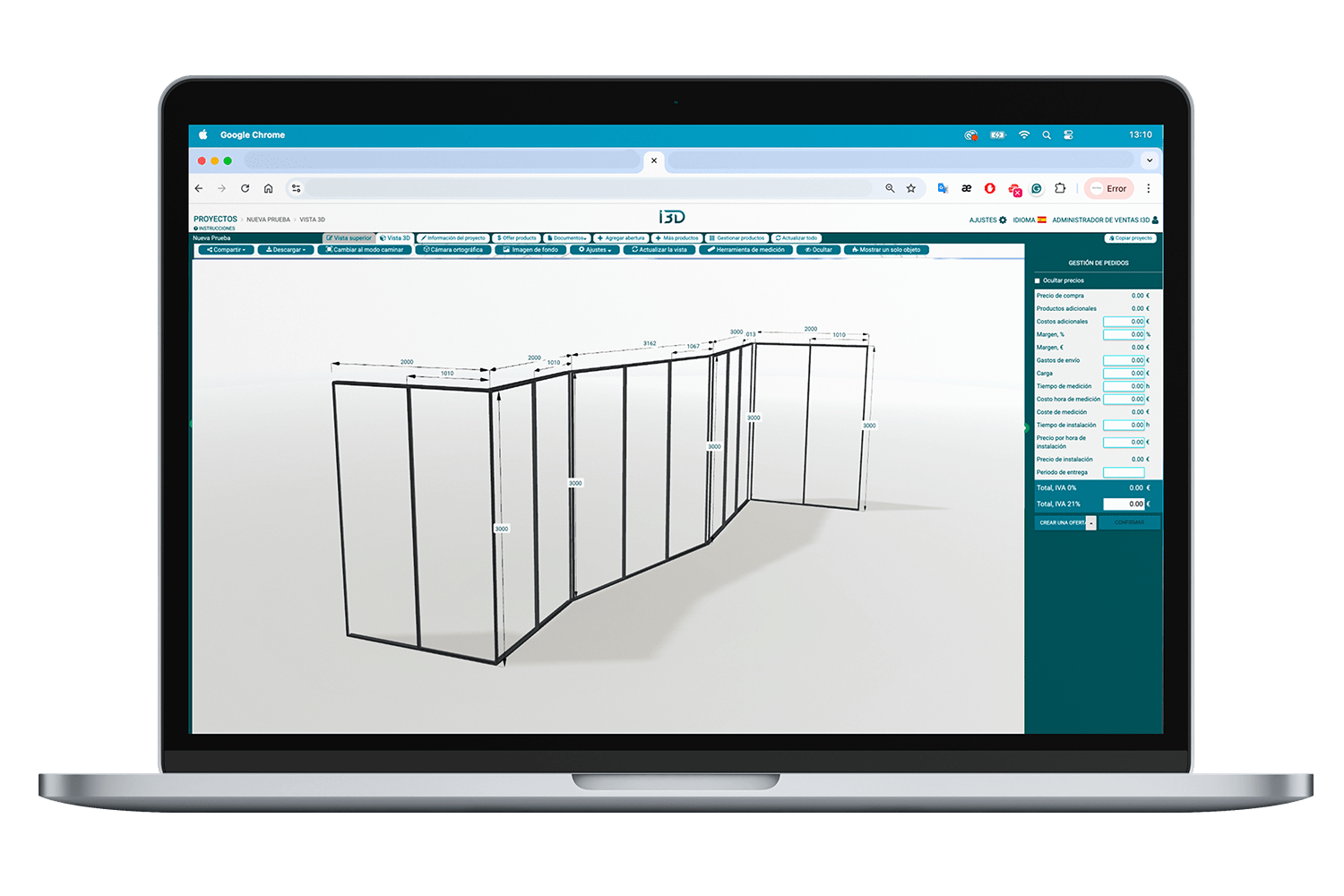

But the best part of the Glazing Configurator is that at the same while you generate this 3D view you will be able to obtain all the documentation related, from quotation to production, and all in just few minutes.

Characteristics

Glazing

Glazing can be used as a stand-alone product or added to an existing structure. Normally the glazings are sliding, folding or fixed.

Common configuration parameters

- Glass type & thickness

- Lock Yes/No/Type

- Handedness

- Split option equal/ std width

- Number of door leaves

- Stocking location

Document examples

Add-on options

Factory Order System

Control your dealer network with the i3D Dealer module. The flow of project information between the dealer and the client can be handled in the same place, making all the process easier and faster for you and your products.

B2C Configurator

Sell configurable products on your website by embedding an easy-to-use configurator in your webshop, receive requests online for quotations or enquiries, and accelerate your deals.

Integrations

Automate data flow by integrating i3D Configurator with other software in your company. Streamlines your business processes by unifying all the data related from sales to production and management.

CoverGlobal LTD

Proven reliability

After developing the world’s first balcony and terrace glazing system that slides over different angles, CoverGlobal were looking a simpler and quicker way to sell and design even the most complex glazing systems without errors.

We configured few models of different, complex glazing products. With i3D Configurator, sales do not need to know every detail of the products because the right configuration options are built into the system. Automated picking lists, glass ordering and production documents improve Cover’s production control, allowing products to be completed on time and overall control to be more easily maintained.